As the world increasingly shifts towards sustainable technologies, the demand for rare-earth elements (REEs) has surged dramatically. These critical materials, particularly neodymium (Nd) and dysprosium (Dy), play a vital role in the production of high-performance magnets that are indispensable in electric vehicles (EVs) and renewable energy sources, such as wind turbines. In response to this growing demand, innovative methods for recycling these elements from end-of-life products are crucial. Recently, researchers from Kyoto University have introduced a groundbreaking technique called the selective extraction-evaporation-electrolysis (SEEE) process, which promises to enhance the efficiency of REE recycling while minimizing environmental impact.

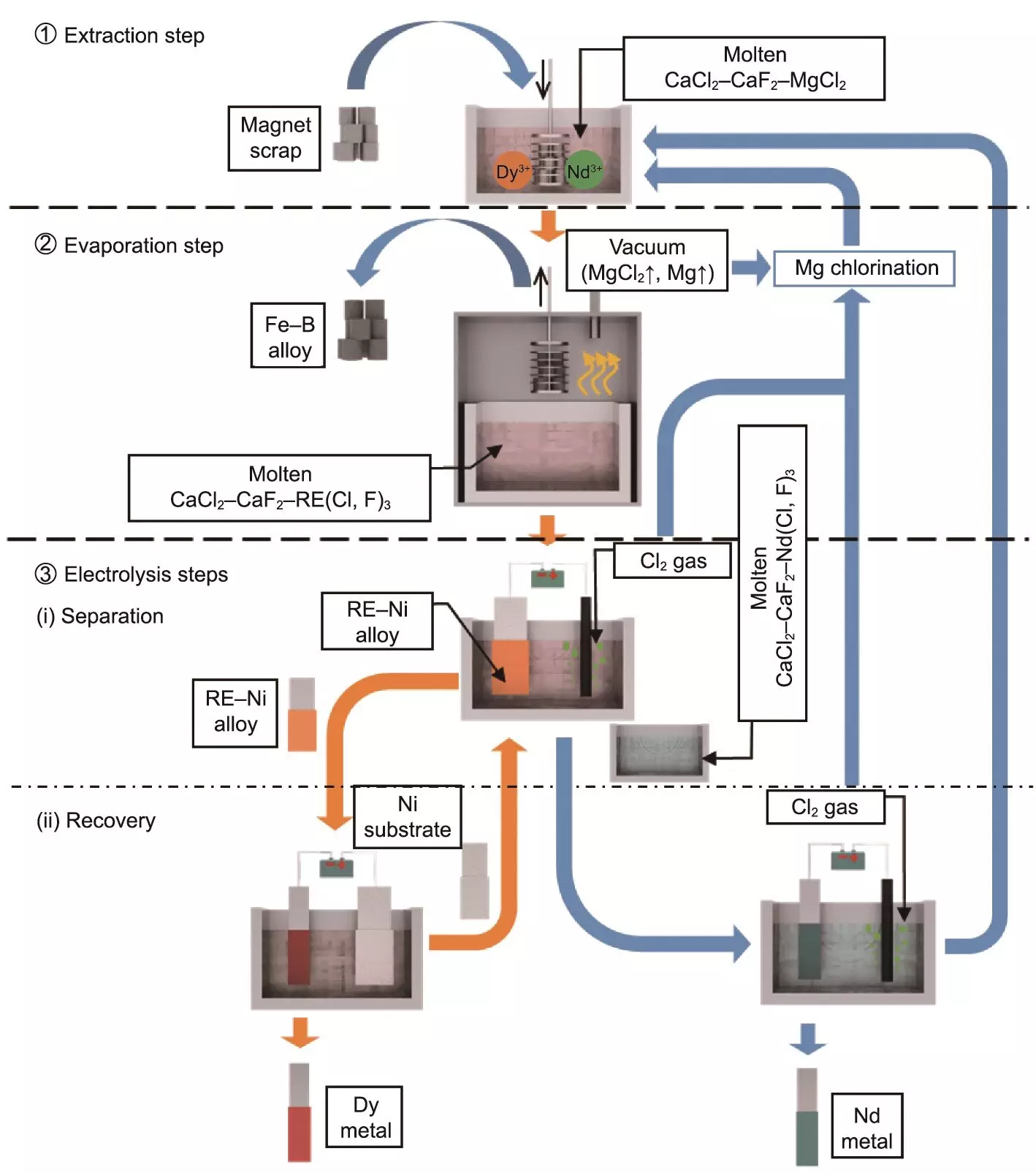

The SEEE process is a meticulous approach that encompasses three major phases, each designed to improve the recovery and purity of REEs. The first stage, selective extraction, employs a specialized molten salt mixture containing calcium chloride (CaCl2) and magnesium chloride (MgCl2). By introducing calcium fluoride (CaF2), the researchers effectively mitigate evaporation losses, thereby enhancing the efficiency of the extraction process.

The second stage, selective evaporation, serves to eliminate residual byproducts and focusing on REE concentration. This step not only prepares the materials for the final stage of recovery but also ensures that the remaining contaminants do not compromise the quality of the extracted elements. Finally, selective electrolysis is carried out, where the purified REEs are separated based on their electrochemical properties, allowing for the retrieval of high-purity Nd and Dy metals.

Efficiency and Environmental Impact

The results from the implementation of the SEEE process reveal significant advancements over traditional recycling techniques. The reported recovery rates stand at an impressive 96% for neodymium and 91% for dysprosium, with both elements reaching purities exceeding 90%. These figures suggest that the SEEE process is not only efficient but also capable of providing materials critical for the green technology sector with a minimal ecological footprint.

Traditional methods of recycling REEs are often mired in complexity and associated with high energy consumption, which can detract from their sustainability credentials. The SEEE process offers a refreshing alternative: it is designed to be both precise and environmentally conscious—a necessary evolution in recycling technology in an era defined by climate change and resource depletion.

The implications of the SEEE process extend well beyond the realm of electric vehicles and wind energy. As the global appetite for sustainable energy solutions grows, the demand for effective recycling methods becomes increasingly urgent. By reducing dependency on newly mined REEs—which frequently incur significant environmental costs—the SEEE process holds the potential to fortify the supply chain for these crucial elements while promoting an eco-friendly approach to material recovery.

Moreover, the researchers posit that the SEEE process could also be adapted for various industrial applications beyond magnet recycling. For instance, its methods could potentially be leveraged for the reprocessing of nuclear fuels, thereby creating new avenues for sustainability across diverse industries.

Despite the promising outlined capabilities of the SEEE process, the research team has acknowledged that further technical studies are necessary to transition this method into practical, industrial applications. While the preliminary findings signal a noteworthy advancement in materials recycling, they also highlight a critical phase of exploration and adaptation that lies ahead.

The study stresses the importance of ongoing research to align emerging technologies with global sustainability objectives. As ecological considerations become ever more salient in policymaking and corporate strategy alike, innovations like the SEEE process are instrumental in bridging the gap between technological advancement and environmental responsibility.

The innovative SEEE process developed by Kyoto University’s research team represents a significant leap forward in the recycling of rare-earth elements. It demonstrates a model of efficiency and sustainability that aligns with the demands of a carbon-neutral future. As nations strive to reaffirm their commitment to combatting climate change, embracing and investing in breakthroughs in recycling technology will undoubtedly play a fundamental role in shaping a more sustainable world.