The manipulation of materials under pressure has long intrigued scientists, particularly within the realms of material science and engineering. In a groundbreaking study led by Valery Levitas at Iowa State University, new findings challenge previously held beliefs regarding the transformation of silicon under conditions of high pressure and plastic shear deformation. This study not only touches upon fundamental scientific inquiries about material properties but also has real-world implications for various industries, particularly electronics.

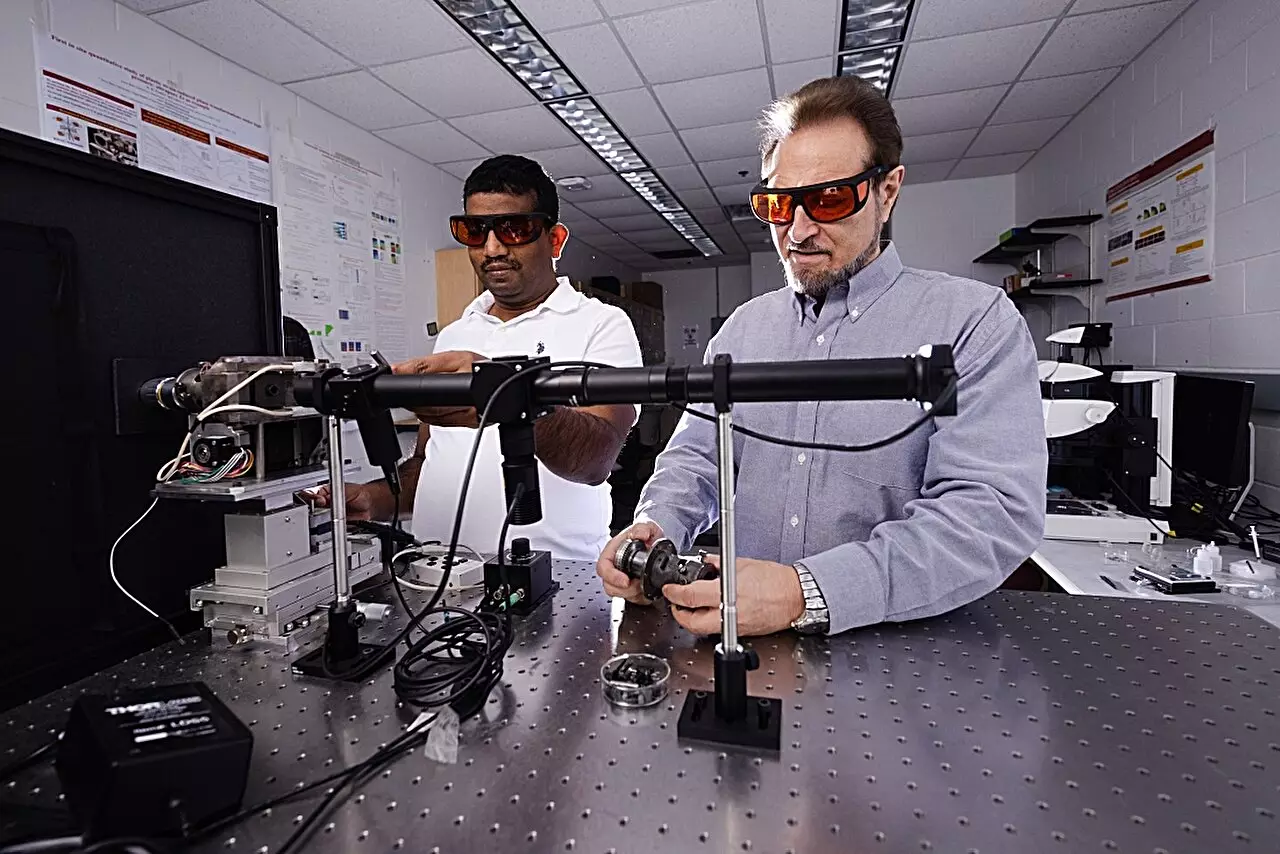

Levitas, who moved to the U.S. in 1999, harnessed the capabilities of a specialized instrument known as the rotational diamond anvil cell. This advanced device enables researchers to exert immense pressure on materials, allowing for real-time observation of phase transformations. The use of such sophisticated tools is paramount; they provide insights that can verify theories concerning the behavior of materials at the atomic level. By applying this technology, researchers can study questions like how crystal structures change and how these changes might lead to new, advantageous material properties.

Among the notable findings reported in the journal *Nature Communications*, silicon was found to exhibit unique phase transformations that had not previously been documented when subjected to controlled plastic deformation. The pivotal aspect of this research lies in the conception that silicon can undergo a significant phase change from “Si-I” to “Si-II,” under much lower pressure thresholds than traditionally thought. While prior studies indicated that this transformation occurred at pressures around 16.2 gigapascals, Levitas and his team discovered that a mere 0.3 gigapascals was sufficient when combined with plastic shear deformation. This impressive reduction in required pressure—by a factor of 54—significantly alters the landscape of material manipulation and emphasizes the relevance of deformation techniques.

What makes this research particularly compelling is the team’s focus on small particle sizes—ranging from 1 millionth of a meter to sizes even smaller—subjected to intricate strains. By delving into the relationship between plastic strain-induced transformations and phase changes, the researchers uncovered that the microstructure of materials holds the key to inducing these transformations, rather than merely altering the shape or dimensions of the material samples. This distinction underscores a shift in understanding what mechanisms can be leveraged to access high-performance materials without the impracticality of extreme pressure conditions.

Levitas has expressed optimism regarding the applicability of these findings for industrial processes, particularly in electronic material fabrication, where the properties of silicon play a critical role. The ability to access high-pressure phases at comparatively modest pressures opens up the potential for creating nanostructured materials or composites that possess optimal electronic, optical, and mechanical characteristics. Not resting solely on theoretical implications, this research indicates a tangible path forward for industries requiring advanced materials without the constraints imposed by traditional high-pressure methodologies.

For Levitas and his collaborators, the development of this approach represents a significant shift in research paradigms. The idea that phase transformations could occur at lower pressures is rooted in a comprehensive, two-decade-long exploration of material science. Such insights demand a reevaluation of existing theories regarding pressures required for phase changes, leading to potentially unprecedented opportunities for materials design and engineering innovation.

The work spearheaded by Valery Levitas and his team signifies not just a scientific advancement but also a transformative approach in material sciences. By uncovering the complexities of silicon under pressure and leveraging advanced tools like the diamond anvil cell, researchers are redefining how we understand material properties and their applications in real-world scenarios. This research lays the groundwork for future explorations that marry theoretical frameworks with practical outcomes, heralding a new era of innovative material research.