In the realm of civil engineering, the exploration and development of concrete materials have been vital to ensuring the safety, efficiency, and longevity of structures. Most recently, a significant advancement has emerged in the understanding of ultra-high-performance concrete (UHPC) confined by fiber-reinforced polymers (FRP). A team of researchers hailing from Huazhong University of Science and Technology and Southern University of Science and Technology has embarked on a study that culminated in a novel stress-strain model. This initiative not only sheds light on the compressive behavior of FRP-confined UHPC but also fills a critical void in existing structural engineering paradigms.

As construction techniques evolve, so too must the models that engineers depend on to analyze materials. While traditional stress-strain models have successfully interpreted behavior in normal-strength concrete (NSC), they fall short when applied to the complexities presented by UHPC. The enhanced properties of UHPC, notably its exceptional strength and durability, establish its status as a preferred material in modern construction. Nevertheless, the dual challenge of understanding its behavior under various confinement conditions—particularly when encompassed by FRP—has posed a significant barrier to optimal application.

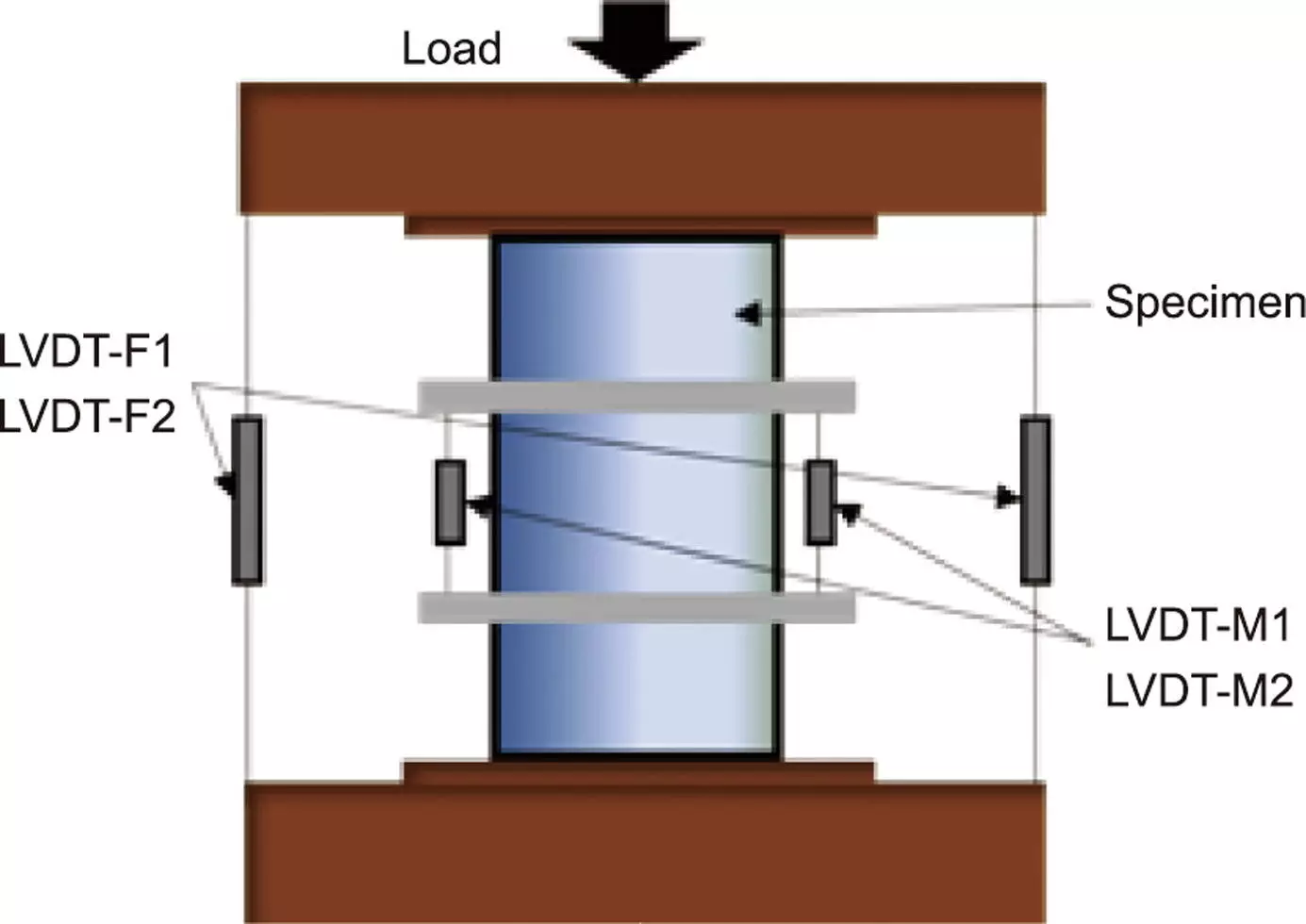

The research team undertook a comprehensive examination of UHPC under concentric compression when confined with FRP. By performing a series of controlled experiments, they scrutinized the material’s response and identified the pivotal failure mechanisms at play. One notable discovery was that the existing assumption of stress-path independence, valid for NSC, did not hold for UHPC subjected to identical confinement conditions. This insight catalyzed a critical re-evaluation of conventional models, prompting researchers to innovate and adapt their approaches.

A key finding of the research pointed to the formation of significant diagonal cracks in the UHPC when FRP confinement is applied. This cracking led to non-uniform lateral expansion, resulting in a decrease of effective confining pressure. Such behavior prompted the research team to question long-standing assumptions about stress distribution and confinement effectiveness traditionally applied to NSC. Understanding these discrepancies allowed for the refinement of existing models to better simulate the behaviors observed with UHPC.

In light of their findings, the research team developed an enhanced analysis-oriented model that incorporates stress-path dependency—a feature absent in precedent formulations. By introducing adjustments to the confining pressure and establishing a new equation to address the confining pressure gap, this model provides engineers with a robust tool for predicting the stress-strain characteristics of FRP-confined UHPC. Their comprehensive database of test results serves as a foundation for validating these predictions, demonstrating the model’s efficacy in accurately reflecting real-world behavior.

The implications of this research are profound. By offering a more nuanced understanding of UHPC’s compressive behavior, the study enhances the safety and design capabilities of structures that utilize these advanced materials. Engineers are now equipped with a model that not only increases confidence in their analysis but also opens the door to innovative designs that fully leverage the properties of UHPC and FRP systems.

The introduction of this new model promises to be a game-changer in the concrete technology landscape. With accurate predictions of FRP-confined UHPC behavior, construction professionals can explore more efficient and safer design methodologies for a myriad of structural applications. This research marks an important milestone, paving the way for ongoing studies that can further refine our understanding of high-performance concrete’s potential.

As the construction industry increasingly prioritizes resilience and performance, research like this lays the groundwork for innovative practices that address modern challenges. The advancements made in stress-strain modeling for FRP-confined UHPC represent not just a technical achievement but a leap toward transforming the construction industry’s approach to material science, safety, and structural integrity. The researchers stand at the forefront of a movement that promises not only to improve current practices but also to inspire future advancements in the realm of high-performance concrete applications.